Drilling fluids are designed to contribute in achieving the main planned objectives (ex: minimal nonproductive time). Operational problems are interrelated which makes them difficult to be solved. It is not uncommon to face loss circulation situation with taking an influx. The lost circulation affects the height of mud column which reduces the bottom pressure that will be less than the pore pressure and allow formation fluids to flow into the wellbore. Designing the drilling fluids in proper way can help to avoid such problems and get to the targets.

I-Loss of Circulation

Lost circulation is the phenomenon of losing mud into the formation. Mud losses can be caused by many processes. Fracture pressure can be exceeded by drilling through the formation using a high mud weight that can exert high hydrostatic pressure. Surging the formation is also another process which can lead to exceeding the fracture pressure of the drilled formation and losing mud in it. Lost circulation can lead to other drilling problems like stuck pipe, well control situation or even damaging the production zone. Curing the losses quickly and effectively is very important to carry on drilling operations.

|

| Fig 01- Lost Circulation |

Among the main objectives of drilling operations design is preventing mud losses. Analyzing the data from offset wells can help to choose the appropriate mud weight. Lost circulation material (LCM) can be used routinely in the active system while drilling through probable lost circulation layers. LCM can be pumped with drilling fluids without affecting their rheology or the predesigned properties.

When drilling through thief zones, the priority is maintaining a full hole with mud in order to get a safe hydrostatic pressure that will not fall below the formation pressure and allows formation fluids to flow into the wellbore generating what it is called a kick. Loss zones can also pose risks of differential sticking which can be avoided by rotating and reciprocating the drill string while preparing the LCM pill.

Treating losses which is based on the LCM can be performed by using many types of them with different sizes. Paper, calcium carbonate, mica or even nutshells are conventional and relatively inexpensive materials which can be used to cure losses.

Hydratable LCM pills can be used in the case of severe losses. The procedure of using this type of LCM is spotting them at the thief zone depth and applying a relatively moderate squeeze pressure. The Hydratable LCM pills expand at downhole temperature to fill fractures.

Rapid-Set LCM is another type of products which react with the drilling fluids after spotting them at loss zone. They form a flexible and dense plug that can fill the fractures. This type of products has proven its ability to improve the naturel fracture gradient of the drilled formation allowing the use of higher mud weights.

Stuck pipe is among the most expensive problems that can be faced during drilling operations. It can be associated with other problems like lost circulation or well control problems. The situation can be more complicated if the stuck pipe is faced when drilling highly deviated wells.

While drilling through depleted zones, the drill string can stick by differential sticking mechanism. When the pressure in the annulus becomes greater than the formation pressure, the drill string is pushed toward the walls of the well and embedded on the filter cake. In high deviated wells, the situation can be more difficult because the gravitational force contributes in embedding the drill string. Controlling the quality of the filter cake and the lubricity of the drilling fluids can help to reduce the risks of facing the differential sticking.

|

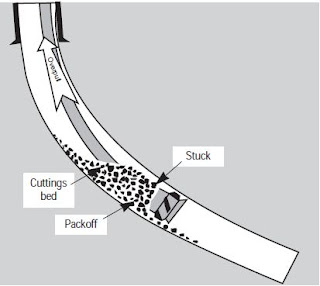

| Fig 02- Stuck Pipe Due to Packoff |

The stuck pipe can be caused also by mechanical mechanisms including keyseating, packoff, wellbore collapse and plastic formations movement. Many parameters can be monitored closely in order to prevent such problems, for example increased torque and drag can give an evaluation about the hole cleaning or tight spots intervals.

According to the mechanism of sticking, the drilling fluid density can be adjusted to avoid stuck pipe. Mud weight can be increased when drilling through plastic formation like salt to control its movement toward the drill string, and can be decreased when drilling through depleted zones to decrease the differential pressure between the annulus pressure and the pore pressure to avoid sticking mechanism.

Some fluids have to be available on the rig site to be used in the case of stuck pipe events. These fluids are designed to destroy the filter cake and provide lubricity in order to allow the pipe to be moved freely. The stuck point can be determined by applying stretching measurement which can help to spot the fluids near the probable stuck point.

Cleaning deviated wells of an inclination between 30° to 60° is among the most difficult issues. The hole cleaning in this situation is related to many parameters. Managing drilling fluid viscosity, annular velocity, pipe rotation speed and pipe eccentricity can minimize hole cleaning problems.

Modeling the down hole condition can be an obstacle because the tests at the rig site are not performed at the down hole conditions which can mislead the results. Some professional softwares are used to determine drilling fluids parameters under down hole conditions like: hydraulic pressure, rheological properties, annular pressure loss, ECD, cuttings loadings and effect of pipe eccentricity. These parameters are validated by the real time pressure while drilling (PWD) data. Getting data from these softwares can help to take some actions to optimize the hole cleaning:

- Adjusting mud properties

- Adjusting rate of penetration (ROP), flow rate, and tripping speed

- Plan for effective sweep program

Programming the hole cleaning sweeps in deviated wells is not the same as the program that can be applied for vertical wells. High viscosity sweeps that can give good hole cleaning in vertical wells might not be a good option for high deviated wells. The eccentric drill pipe creates narrow annular space where no fluids can flow and cuttings bed remains in place. Experience has shown that turbulent flow created by thin drilling fluids is more effective for removing silt bed than the turbulent flow created by the high viscosity fluids.

Some steps are followed to get an effective hole cleaning program:

- The low viscosity sweep is weighted by 3 to 4 ppg more than the drilling fluid used in the hole

- Pumping the sweeps at regular intervals

- Rotating the pipe at speed higher than 60 rpm when the sweep is at the bit

0 Response to "Challenges Related to Drilling Fluids"

Post a Comment